Project Overview

A top US construction equipment manufacturer hired Yas Tech. Services to design a linkage system for their next-generation backhoe loader, targeting improved performance, durability, and maintainability. We delivered a complete solution from concept to production, meeting client and industry standards.

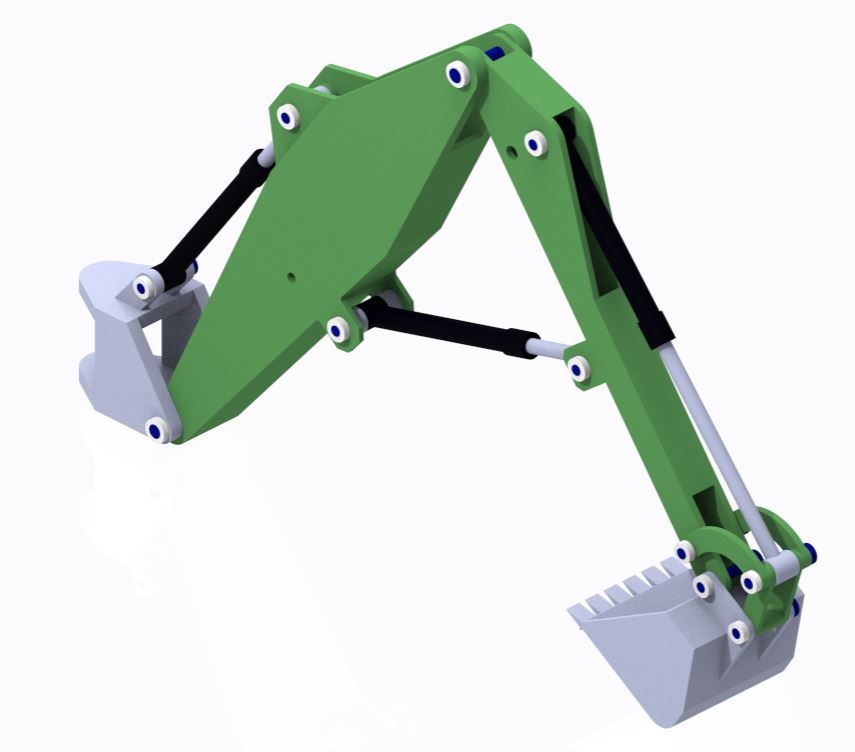

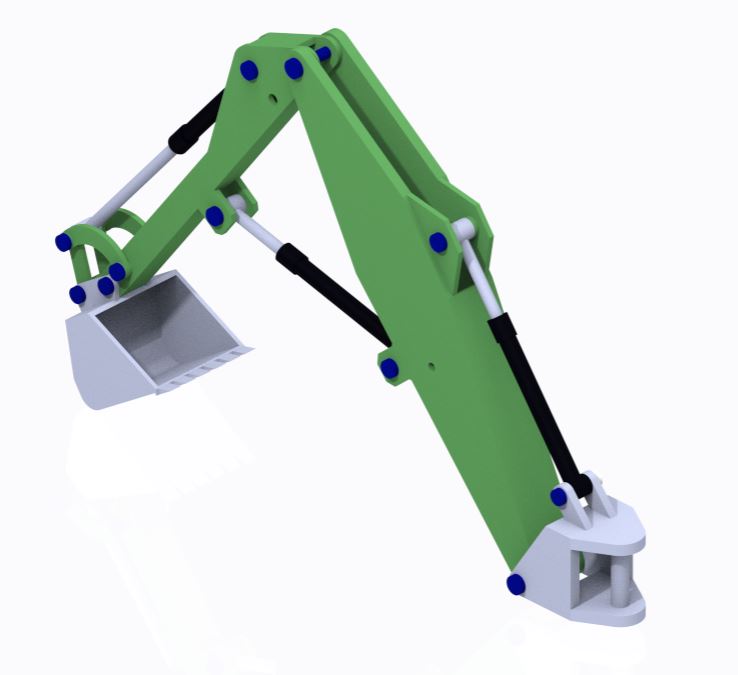

Concept Design

We used CAD software to optimize the linkage system connecting the boom, dipper, and bucket, introducing a modular design for quick part swaps and less downtime.

Design Calculations

We performed:

- Load Analysis: Assessed forces during digging and lifting.

- Kinematic Analysis: Confirmed motion and positioning.

- Material Strength: Chose cost-effective, durable materials.

Stress Analysis

Finite Element Analysis (FEA) pinpointed and reinforced weak spots, ensuring the linkage met safety requirements for heavy-duty use.

Hydraulic Cylinder Calculation and Selection

We calculated cylinder specs for capacity, speed, pressure, and stroke, selecting reliable units with optimized mounting for efficiency.

Prototyping

Partnering with a fabrication facility, we built and tested prototypes with load and cycle tests, verifying performance and durability.

Key Challenges

- Strength vs. Weight: Balanced load resistance and lightweight design.

- Modular Tolerances: Ensured precision with GD&T.

- Hydraulic Integration: Fixed alignment for consistent operation.

Manufacturing Drawings

Detailed drawings with GD&T and tolerance stackup analysis ensured accurate Serial production and assembly.

Regulatory Standards

We complied with:

- ASME B30.22: Boom design safety.

- ASTM Standards: Material strength.

- OSHA Requirements: Operator and equipment safety.

Conclusion

We delivered a high-performing, modular linkage system, showcasing our end-to-end design expertise and exceeding client goals.